IoT

Replicating your business with a digital twin not only allows you to visualise it in real-time, you can leverage data driven decision making to improve it.

Being part of the Industry 4.0 roadshow with Callaghan innovation we used real-time sensor data to demonstrate how actively monitoring manufacturing processes can enrich management's input into on the ground decision making. Targeting high value assets and high risk processes we can detect issues before they happen, driving change and reducing failure.

Implementing IoT can be as simple as powering a 4G connected device and putting some BLE sensors in their proximity. We design and implement solutions based on your primary goals.

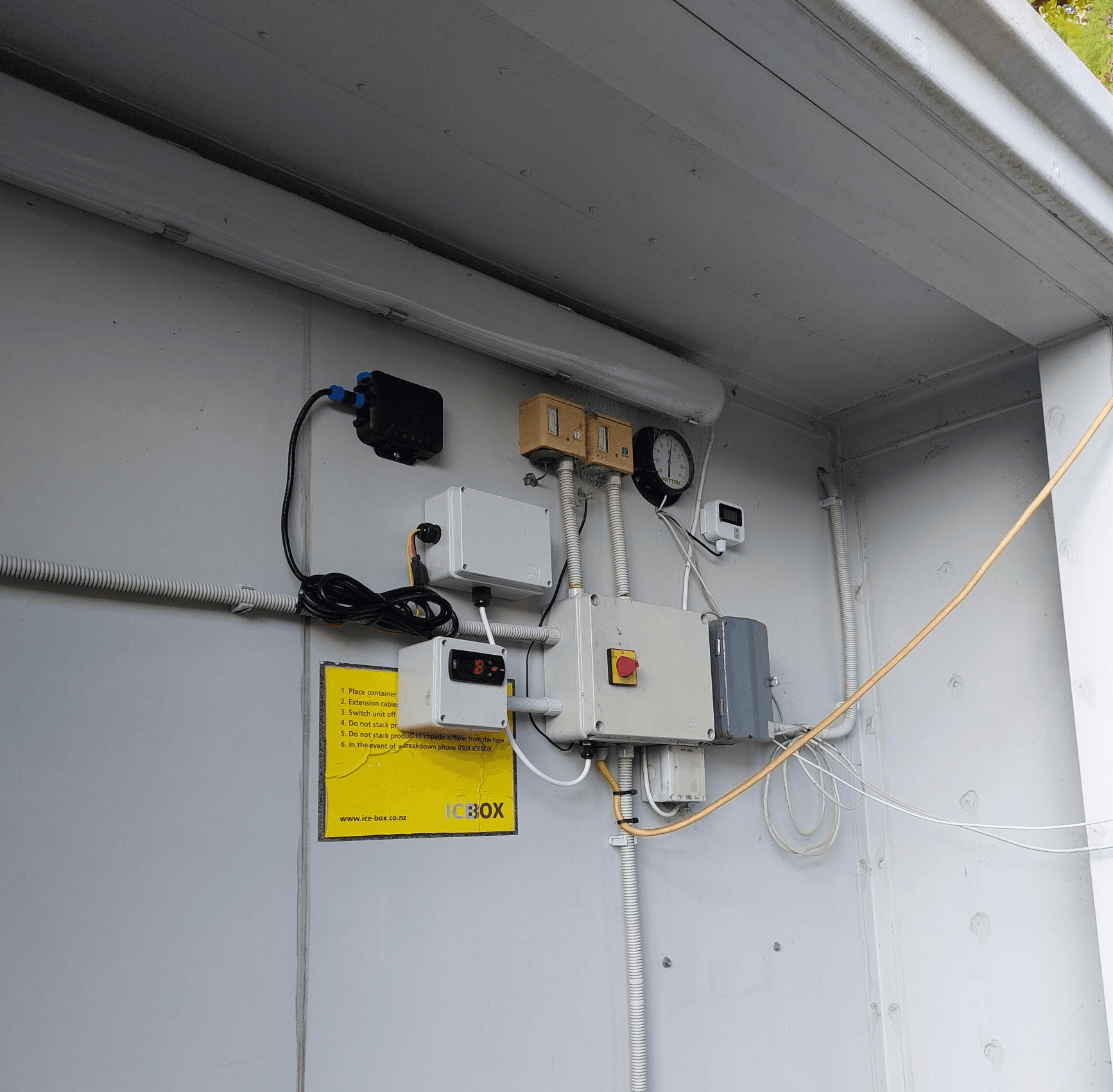

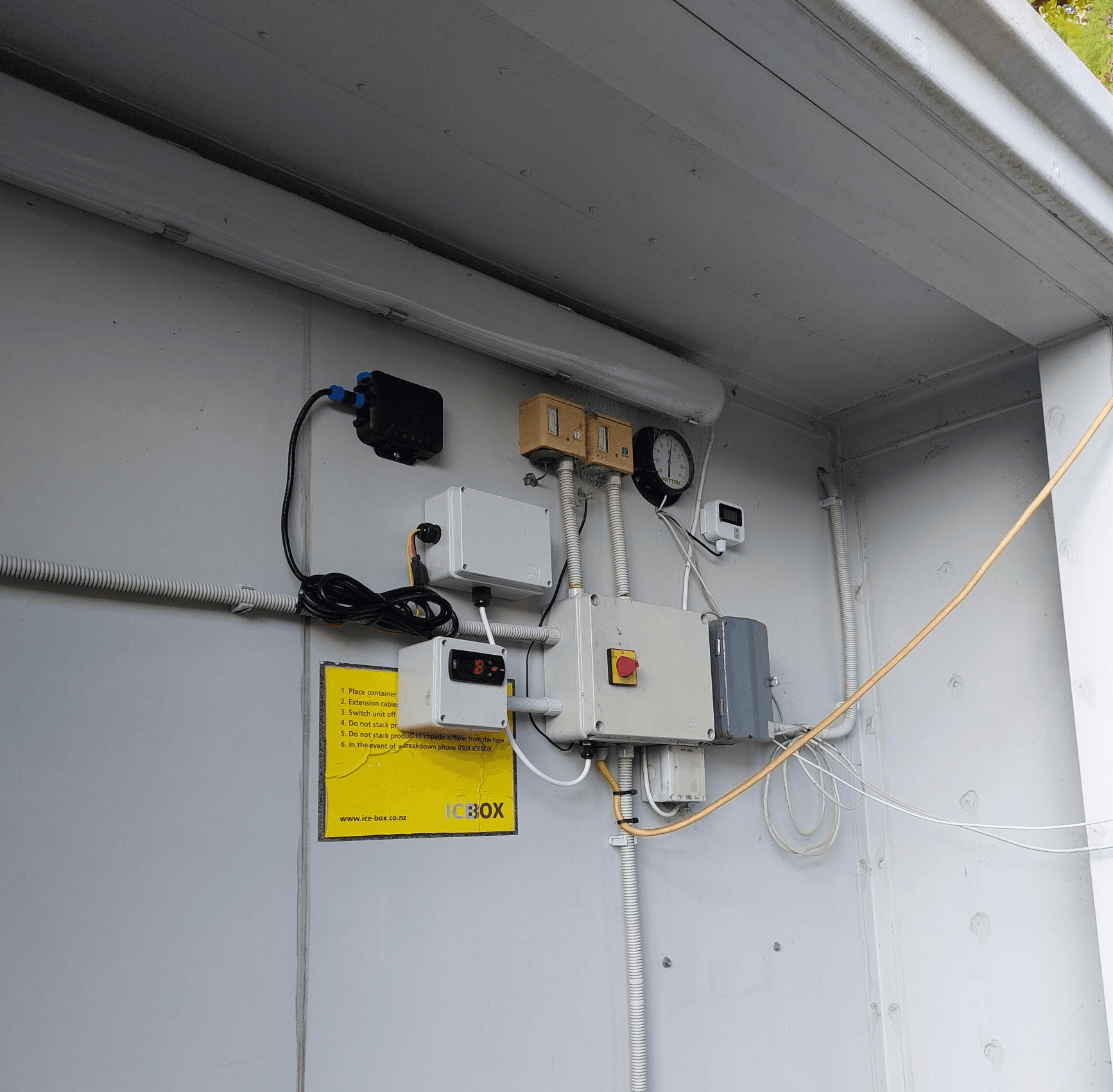

We implement solutions as simple as temperature monitoring for Restaurants and Bars; for dollars per month you can have realtime food temperature monitoring. What is the cost to your business if your prep fridge or freezer fails overnight? Real-time alerts can have your service company notified in realtime of the failure and have the repair priority escalated based on how critical appliance is.

Implementation of more complex solutions such as distributed passive asset monitoring - actively tracking assets gets very expensive quickly with data charges and device costs. With passive BLE asset tracking we can monitor thousands of low to medium value assets for a fraction of the cost. This has been implemented for a major flood restoration business in Auckland shaving thousands off of insurance charges along with costs to the business for lost equipment.

Leveraging our network of partners we can source low cost BLE Equipment, or have custom hardware designed and built for your use case.

Some Custom BLE Devices we offer

- Custom thin probes for monitoring apples core temperature for export requirements - built for Turners and Growers Hastings.

- Actual CO₂ measurement in realtime (not CO₂e) via a BLE device

- Temperature/humidity sensors

- Door open/close sensors

- Staff wearables including wristbands and ID cards

Request a demo and we will show you how easy it is to start your IoT journey.